This is a copper alloy with high electrical conductivity.

When alloyed with chromium and zirconium, wear resistance increases.

Wires can be shaped by erosion.

Consumer Electrical Industrial

Pencil-type & Light Soldering Guns: Tips, Rod Extensions Arcing and Bridging Parts Current Carrying Shafts and Arms

Cable Electrode Holder Jaws

Circuit Breaker Parts Flash Welding Electrodes

Connectors Heat Sinks

Contacts Molds

Electric Motor and Generator Components Plastic Mold Components

Electrical Conductors Requiring Greater Strength than Copper Resistance Welding Machine Electrodes

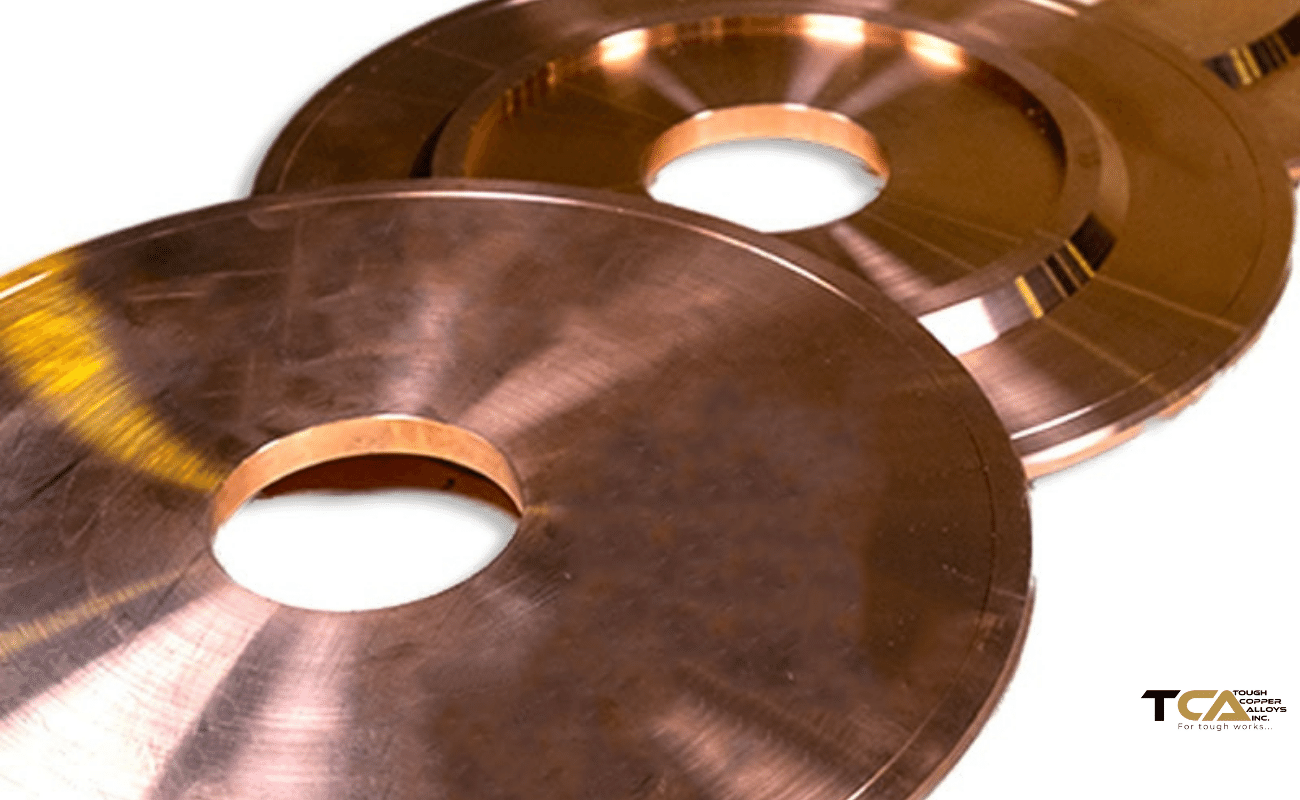

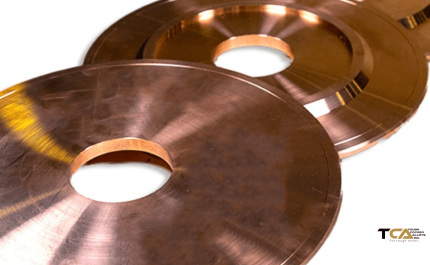

Electrical Connectors Seam Welding Wheels

Electron Tube Grid Side Rods Spot Welding Tips

Parts for Electronic Devices Structural Parts

Semi Conductor Bases Wear Plates on Heavy Equipment

Switch Contacts

Switch Gears

Thermal Conductors Requiring Greater Strength than Copper

Wire, High Temperature