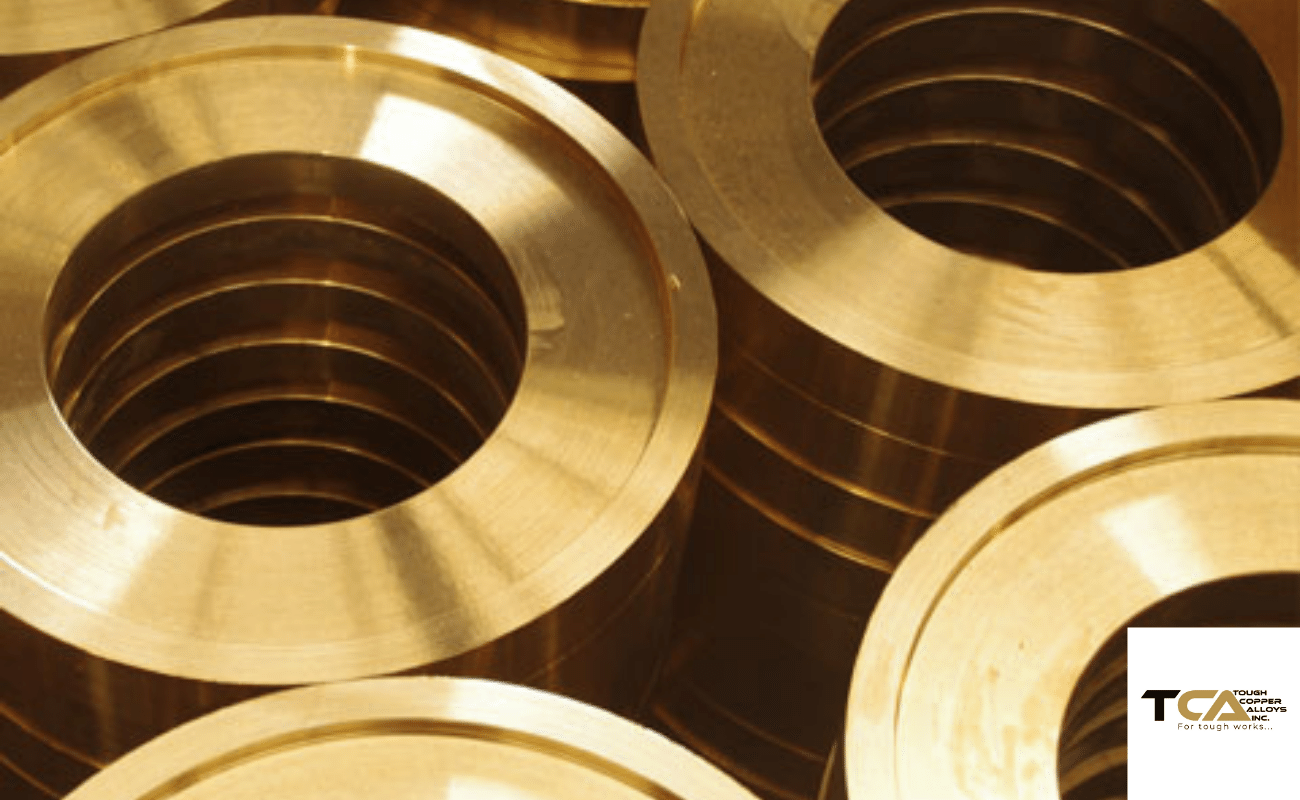

An American low alloy nickel-free aluminium bronze where its unique combined properties of medium strength, high ductility, excellent corrosion resistance in salt water, makes it a popular choice for many commercial and defence marine applications. C61400 aluminium bronze has higher ductility than the nickel aluminium bronzes and can be cold worked to significantly enhance the mechanical properties. C61400 maintains its properties at low temperatures for cryogenic temperatures down to – 452 ºF (-269 ºC). This is a precision wrought alloy that benefits from extreme consistency in properties, fine equiaxed grain structure and low cost volumetric inspection. Furthermore representative test pieces are taken giving accurate analysis of properties from material to component.

| Fasteners | Industrial | Marine | Ordnance |

|---|---|---|---|

| Bolts | Chutes for Abrasive Grains | Fasteners | Blending Chambers |

| Nuts | Condenser Head Plates | Marine Hardware | Mixing Troughs |

| Stringers | Condenser Tube and Piping Systems | Pressure Vessels | |

| Threaded Members | Corrosion Resistant Vessels | Protective Sheathing | |

| Heat Exchanger Tubes | Welded Tanks | ||

| Machine Parts | |||

| Mining Shovels | |||

| Piping Systems | |||

| Sea Water Piping | |||

| Seamless Tubing and Pipe | |||

| Structural Components | |||

| Tanks | |||

| Tube Sheets | |||

| Welded Pipe |