An American nickel-aluminium bronze with a unique combination of properties resulting in high strength, good fatigue, excellent corrosion resistance in sea water. C63200 benefits from a quench and temper heat treatment to enhance mechanical properties. The heat treatment was developed to maximise the corrosion resistance in sea water where it is used extensively in marine defence applications. Its non-sparking and wear properties makes it a excellent choice for weapon handling systems. The alloy has a proven track record having been incorporated in the US submarine build program for many decades and has now been used for wider applications, within commercial marine and petrochemical industries. This is a wrought alloy that benefits from extreme consistency in properties, fine uniform grain structure and low cost volumetric inspection. Furthermore representative test pieces are taken giving accurate analysis of properties from material to component.

Fasteners Industrial Marine

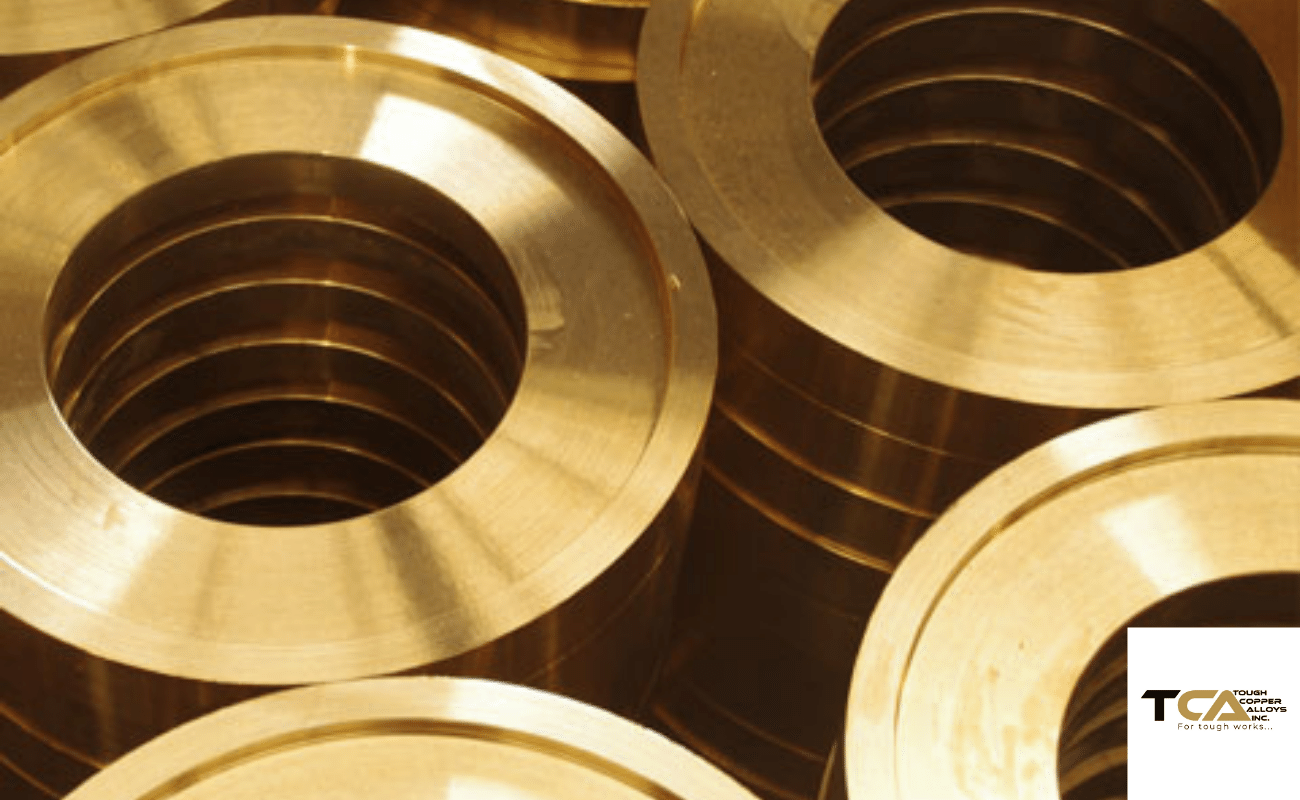

Bolting Bearing Cages Drive Shafts, Marine Service

Fasteners, Sea Water Bushings

Nuts Cams

Sea Water Pump Bodies

Sea Water Valves

Shafts

Sleeve Bearings

Valve Stems