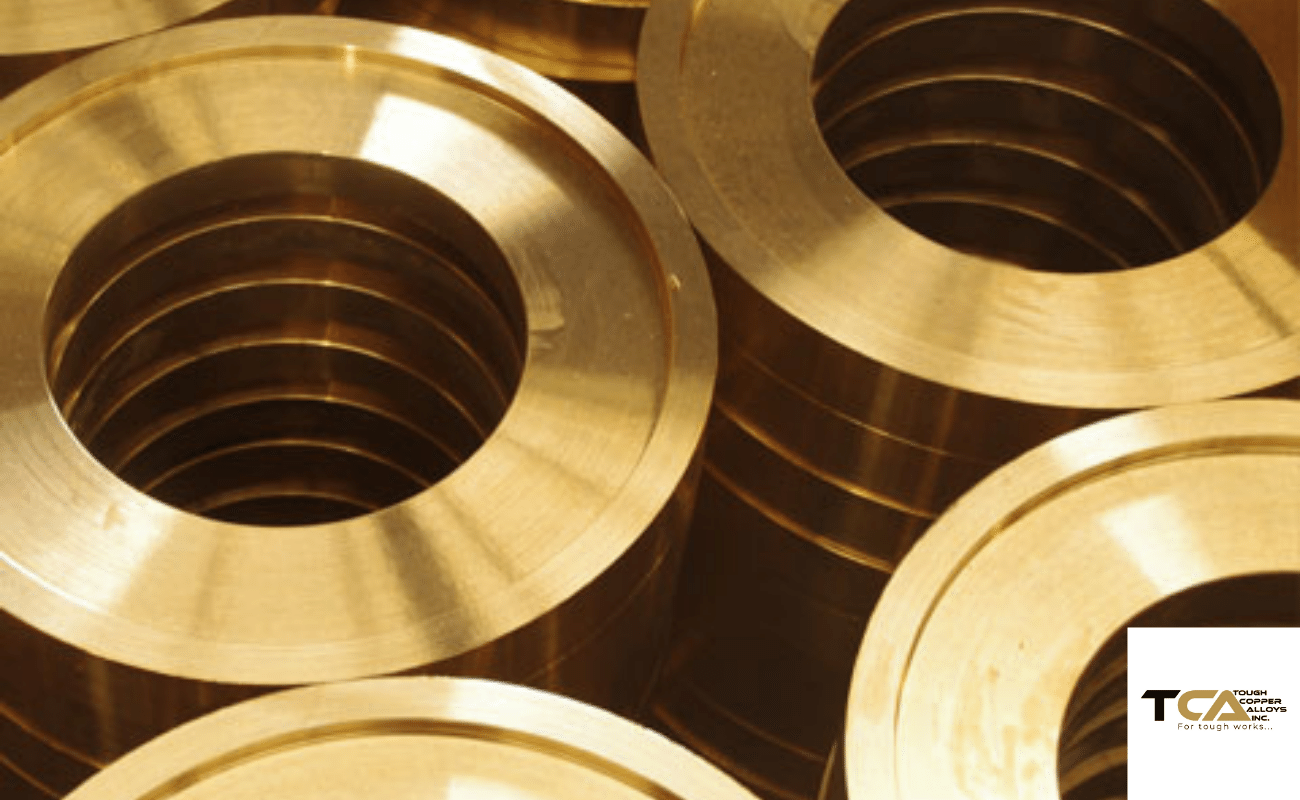

An American free machining Silicon aluminium bronze where its unique combined properties of high strength, good fatigue, excellent corrosion resistance in salt water and low magnetic permeability, make it a popular choice for many sea water applications. C642 aluminium bronze has higher ductility than the nickel aluminium bronzes and can be cold worked to enhance the mechanical properties. The alloy has also excellent anti-galling and bearing properties. The low magnetic properties enables the alloy to be used in Navy applications such as mine hunters, for instrumentation such as sonar, compasses and other sensitive instruments which may also require good corrosion resistance in a hostile environment.

Automotive Electrical Fasteners Industrial Marine

Valve Guides, Automobile Engine Pole Line Hardware Bolts Cams Hardware

Nuts Gears

Valve Bodies

Valve Components

Valve Stems