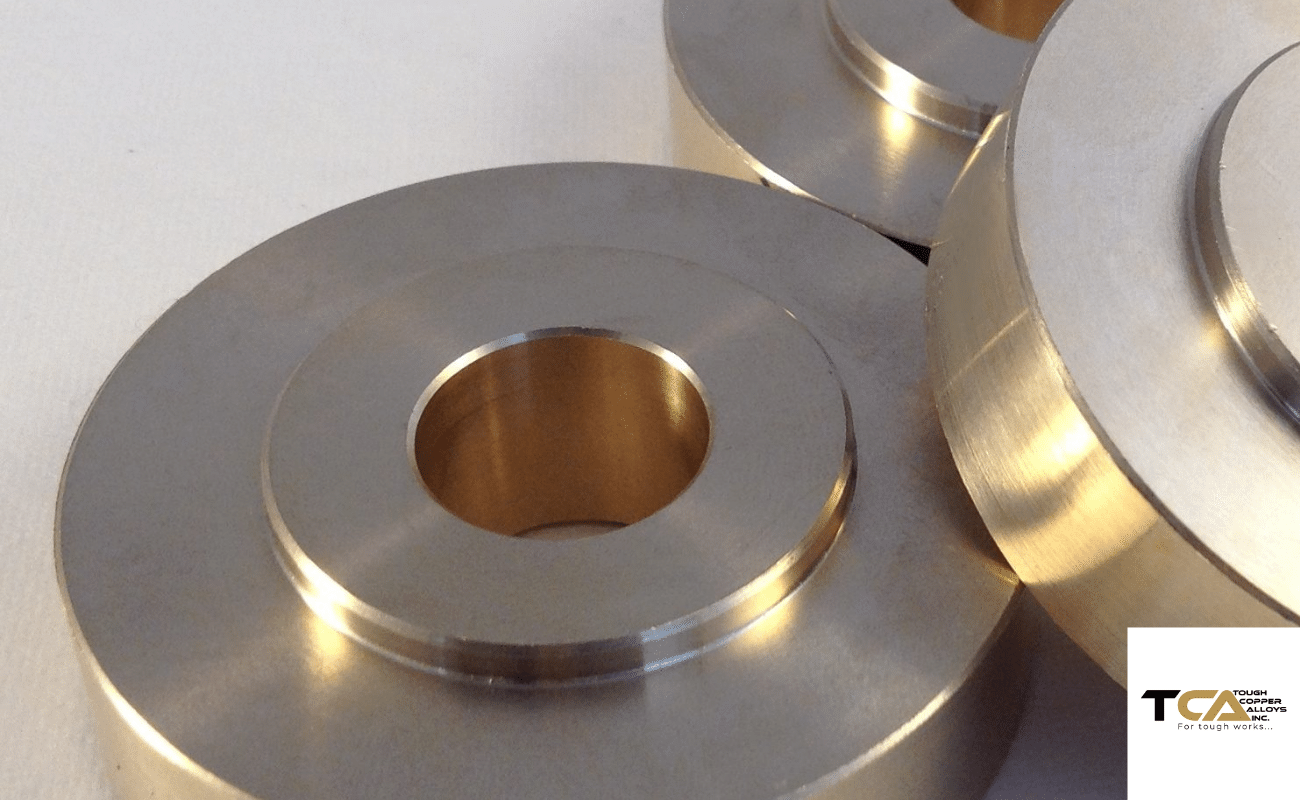

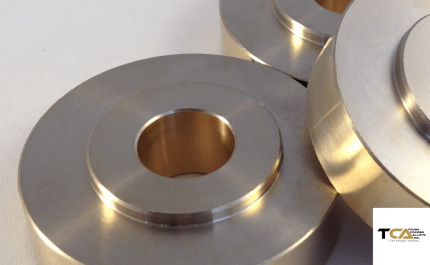

Manganese bronze – copper casting alloy UNS C86200 consists primarily of of copper, zinc, aluminium and manganese bronze. Manganese existing in UNS C86200 provides an attractive chocolate brown color which is commonly used in architecture. The presence of lead in the alloy improves the longevity of the alloy.

Builders Hardware Fasteners Industrial Marine Ordnance

Brackets Screw Down Nuts Bushings Boat Parts Gun Mounts

Structural Parts Cams Clamps

Frames Marine Castings

Gears Rudders

High Strength Machine Parts

Hooks

Marine Racing Propellers

Pressing Dies for Wood Pulp

Shafts

Struts

Valve Stems

Wear Rings for Pressing Dies for Wood Pulp Industry

Worm Gears