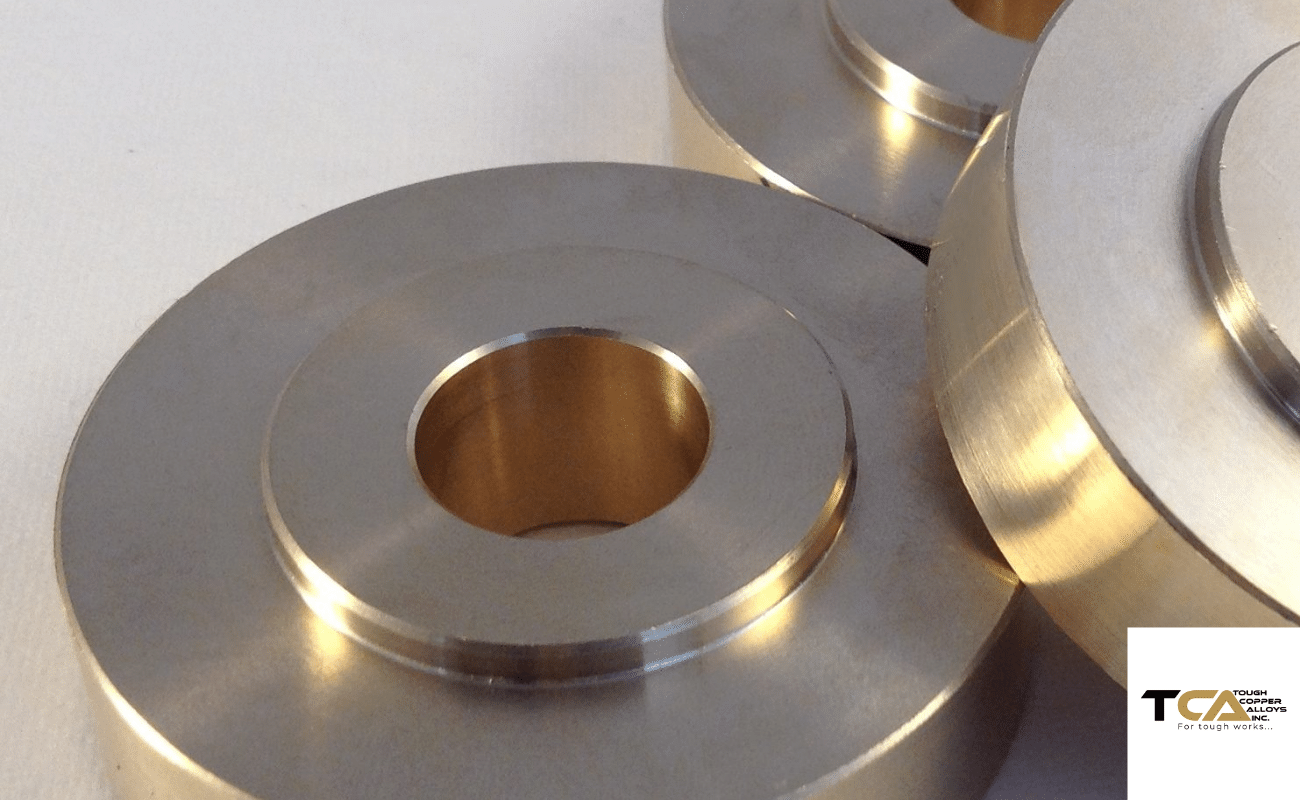

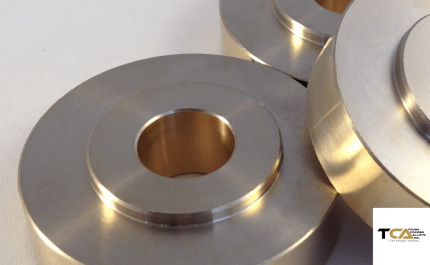

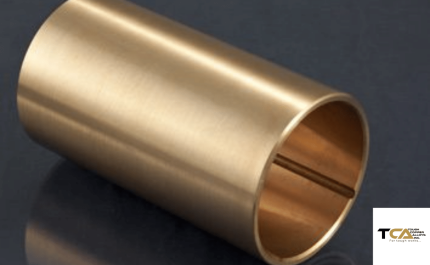

Manganese bronze alloys can operate under very high loads and speeds. Besides excellent mechanical qualities, these alloys have good corrosion resistance. The standard alloy in this group is high tensile C86300, which is comprised of copper, manganese, aluminum, and iron. This combination raises the tensile strength to over 110,000 KSI.

Automotive Builders Hardware Electrical Industrial Marine

Weld Guns Brackets Electrical Hardware Compressors Boat Parts

Forming Dies for Wood Pulp Industry Clamps

Frames Covers for Marine Hardware

Gears Propellers for salt and fresh water

Hooks Rudders

Lever Arms

Machinery

Machinery Parts (Substituted for Steel and Malleable Iron)

Machinery Parts requiring High Strength

Pressing Dies for Wood Pulp

Struts

Wear Rings for Pressing Dies for Wood Pulp Industry