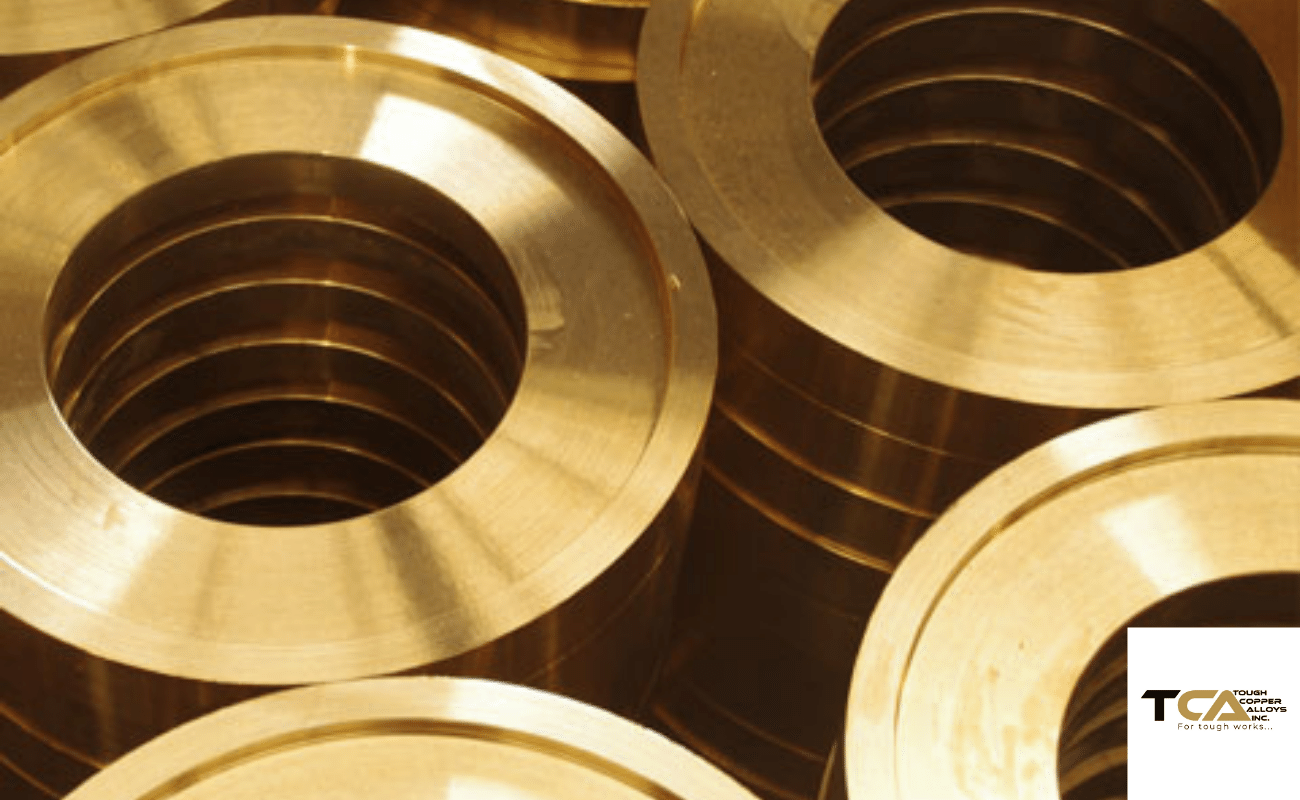

Aluminium bronze is an alloy, which consist of about 6% of nickel and iron, and 9 to 12% of aluminium. It has a golden color.

The UNS C62400 copper alloy has high corrosion resistance, and good strength, and can be heat treated to improve/modify their properties.

Fasteners Industrial

Nuts Bushings

Cams

Drift Pins

Gears

Hydraulic Bushings

Tie Rods

Valve Balls

Wear Plates

Welding Wire