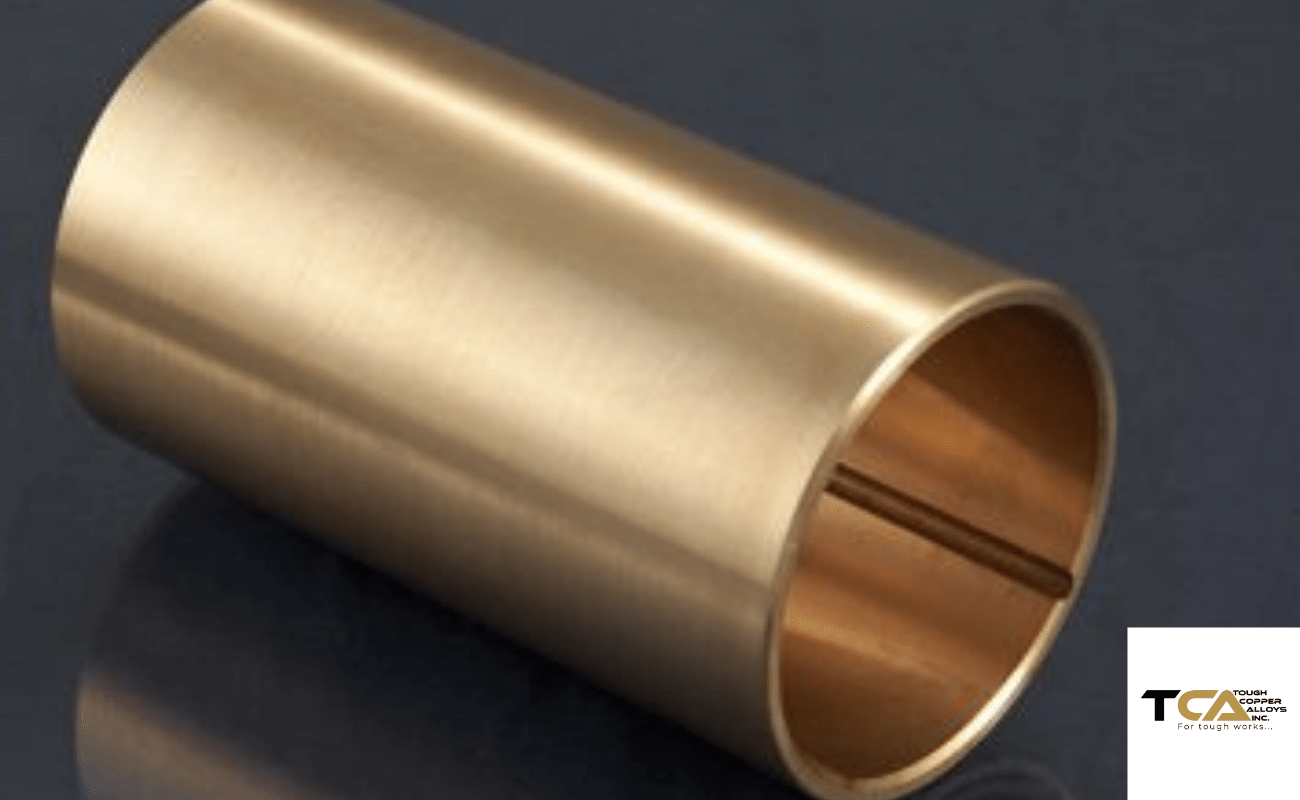

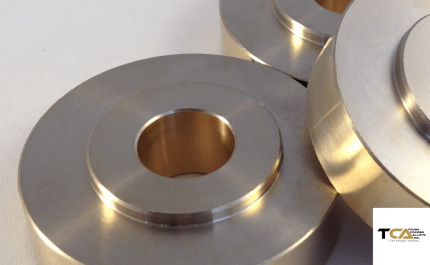

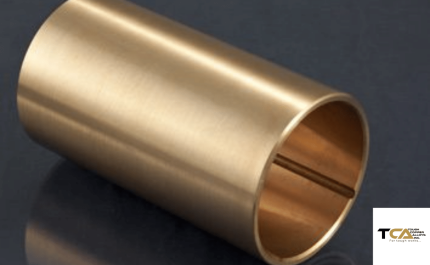

C72900 is an extruded and drawn, spinodal hardened, copper nickel-tin (CuNiSn) bronze alloy. It is great in high-strength applications. It resists mechanical wear, galling, stress relaxation, corrosion and erosion. It is non-magnetic and easy to machine into complex components. It is also and ecofriendly material, being that it is lead and beryllium free. C72900 is an excellent alternative to nickel alloys, aluminum bronzes, and beryllium copper.

Electrical Industrial Marine

Connectors Springs Marine Components

Contacts Wire

Controls

Miniaturized Sockets

Relay Elements

Switches