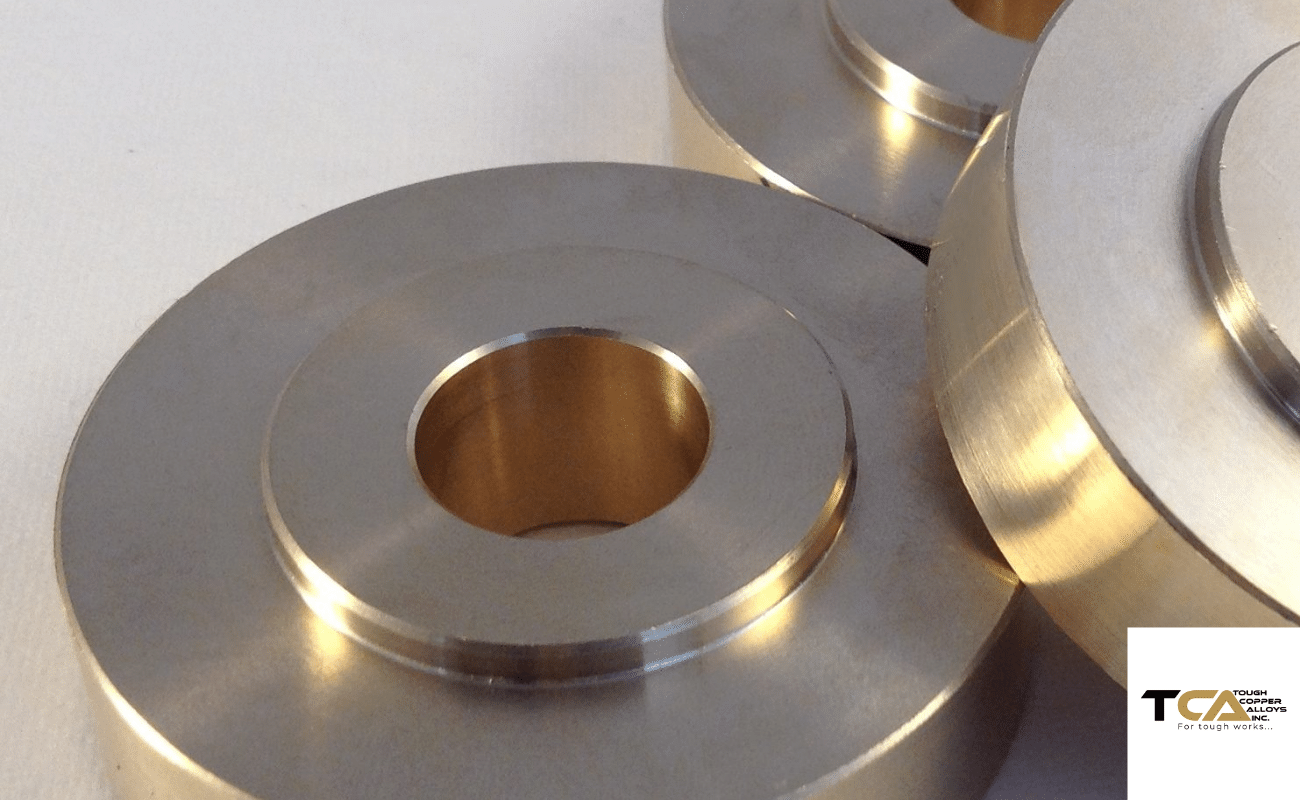

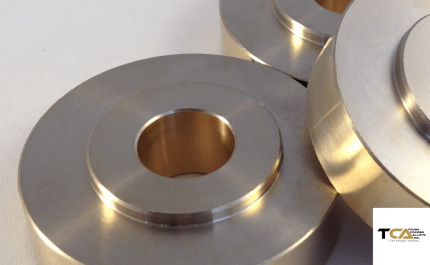

Manganese bronze – copper casting alloy UNS C86300 is an alloy that primarily consists of copper, zinc and aluminium.. The manganese present in UNS C86300 gives a chocolate brown color to the alloy. Copper casting alloy UNS C86300 is used in architecture for its longevity.

| Builders Hardware | Electrical | Fasteners | Industrial | Marine |

|---|---|---|---|---|

| Brackets | Electrical Components | Screw Down Nuts | Bridge Pins | Boat Parts |

| Switches | Bushings | Clamps | ||

| Cams | Covers for Marine Hardware | |||

| Forming Dies for Wood Pulp Industry | Marine Hardware | |||

| Frames | Rudders | |||

| Gears | ||||

| Gib | ||||

| High Strength Machine Parts | ||||

| Hooks | ||||

| Hydraulic Cylinder Parts | ||||

| Large Valve Stems | ||||

| Propellers | ||||

| Slow Speed, Heavy Load Bearings | ||||

| Struts | ||||

| Wear Rings for Forming Dies for Wood Pulp Industry |