An American continuous cast low alloy aluminium bronze containing an addition of iron CuAl9Fe3 (9A).

The iron acts as a grain refiner and gives added strength. The alloy is medium strength and has good corrosion resistance in sea water.

Electrical Fasteners Industrial Marine Ordnance

Electrical Hardware Nuts Acid Resistant Pumps Covers for Marine Hardware Gun Mountings

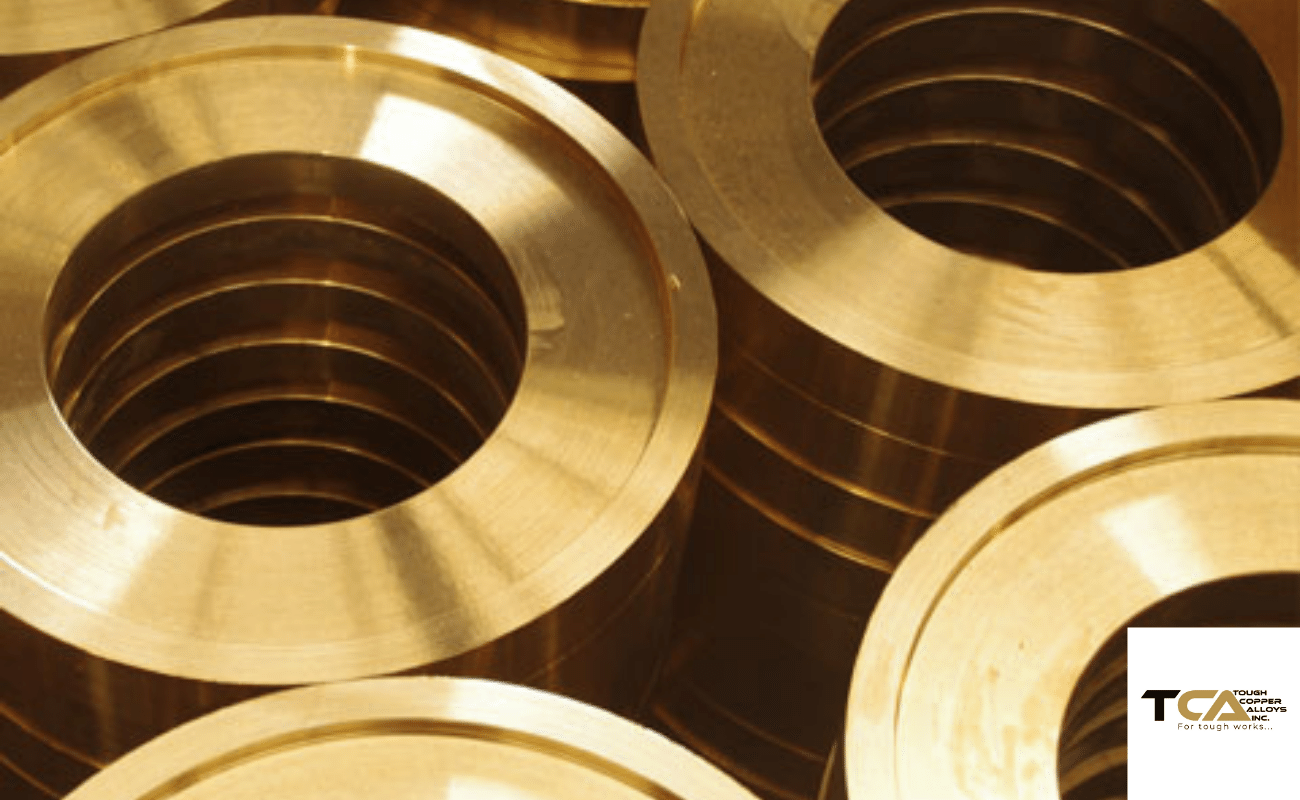

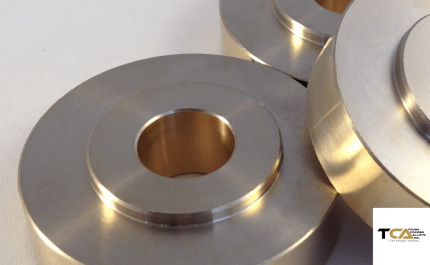

Bearing Liners Marine Engines Gun Slides

Bearings Marine Hardware

Bushings Propellers

Gears

High Strength Clamps

Hot Mill Guides

Hydrant Parts

Large Gear Parts

Mild Alkali Applications

Pickling Equipment

Pickling Tanks

Plungers

Pump Parts

Pump Rods

Thrust Pads

Valve Bodies

Valve Seats

Valves

Wear Plates

Welding Jaws

Worm Wheels

Worms