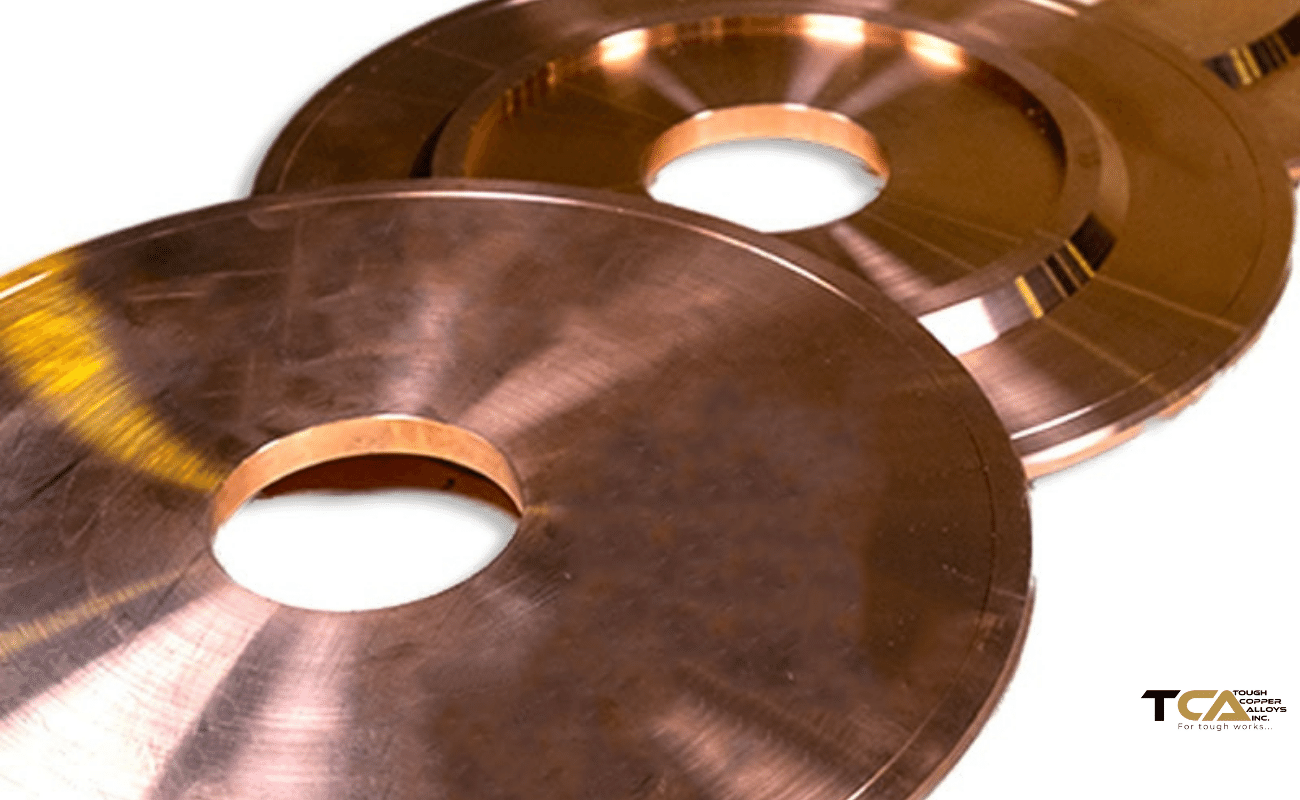

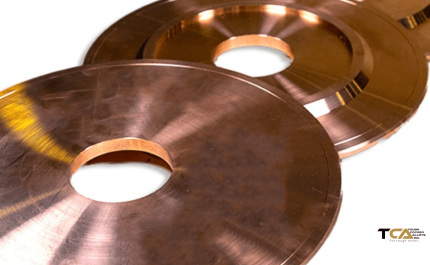

Hard copper alloy with high thermal conductivity and high mechanical properties combined with good hardness and high temperature strength.

Good resistance to tempering. Nitriding and case-hardening are not suitable.

Electrical Fasteners Industrial Other

Conductors Fasteners Die casting plunger tips Stressed Parts

Connectors Resistance and Spot Welding Tips

Fuse Clips Resistance Welding Equipment

Relay Parts Seam Welding Dies

Switch Parts Springs

Tooling for Plastic Molds